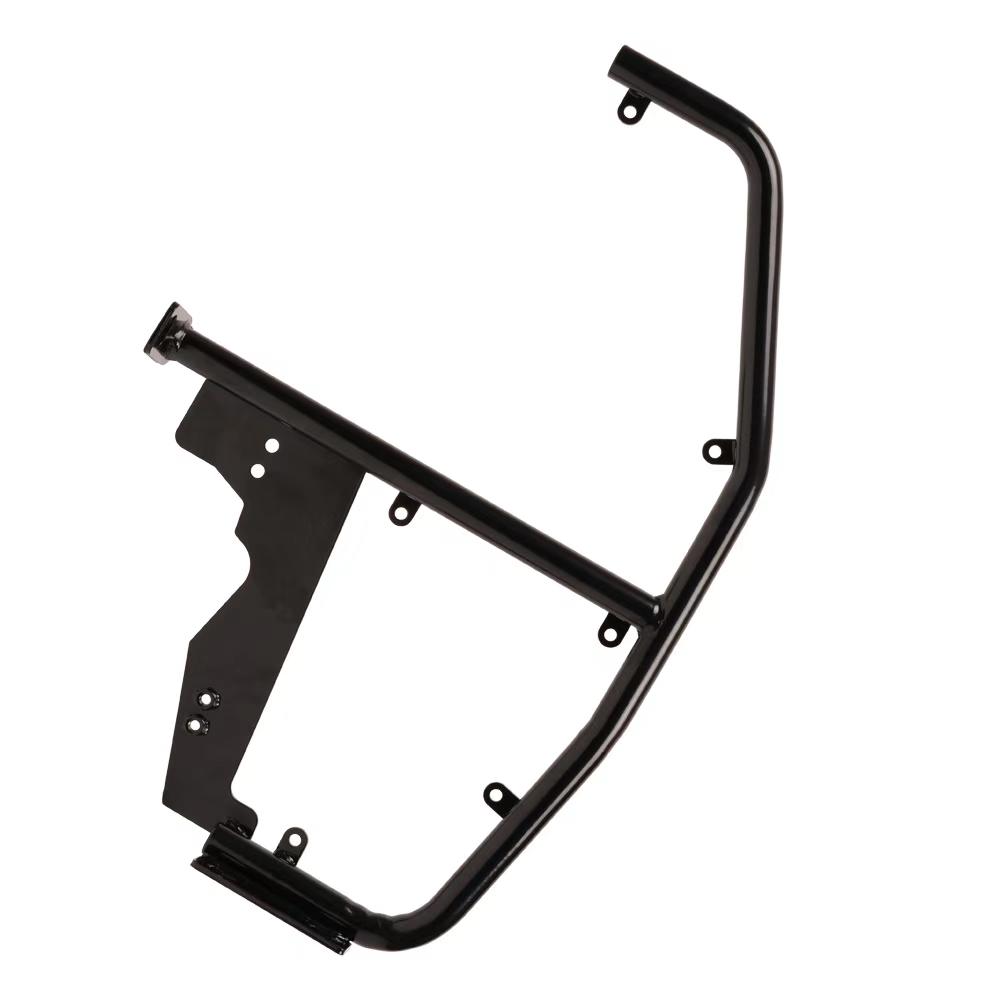

This welding bracket appears to have a complex structure, composed of multiple plates that are laser-cut and bent into matching dimensions, and then welded together using robotic welding technology. It is treated with a black powder coating. This product is mainly used in industrial equipment. The intricate structure of the bracket requires high-precision laser cutting and bending processes to ensure proper alignment and overall stability of the components. Robotic welding technology provides high welding precision and consistency, ensuring the quality and strength of the weld seams.

Welded bracket

The products mainly provide stable structural support for industrial equipment to ensure that the mechanical equipment maintains balance and stability during operation. Its ingenious design allows it to adapt to different mechanical structures.

The main body of the product is welded by pipe bending process and welding robot arm. The use of robot welding to ensure that each position of the welding strength symbol requirements and specific unity. The upper and lower parts of the accessories are made of molds independently developed by our factory through the stamping process.

The surface treatment adopts high quality environmental protection galvanizing process. The galvanized coating provides excellent corrosion and rust resistance to the fittings, while giving them a smooth and beautiful appearance.

You can also click to view more Industrial Equipment parts content:Screen printing equipment accessories,weldment bracket,sliding rail for industrial,Adjustment shims