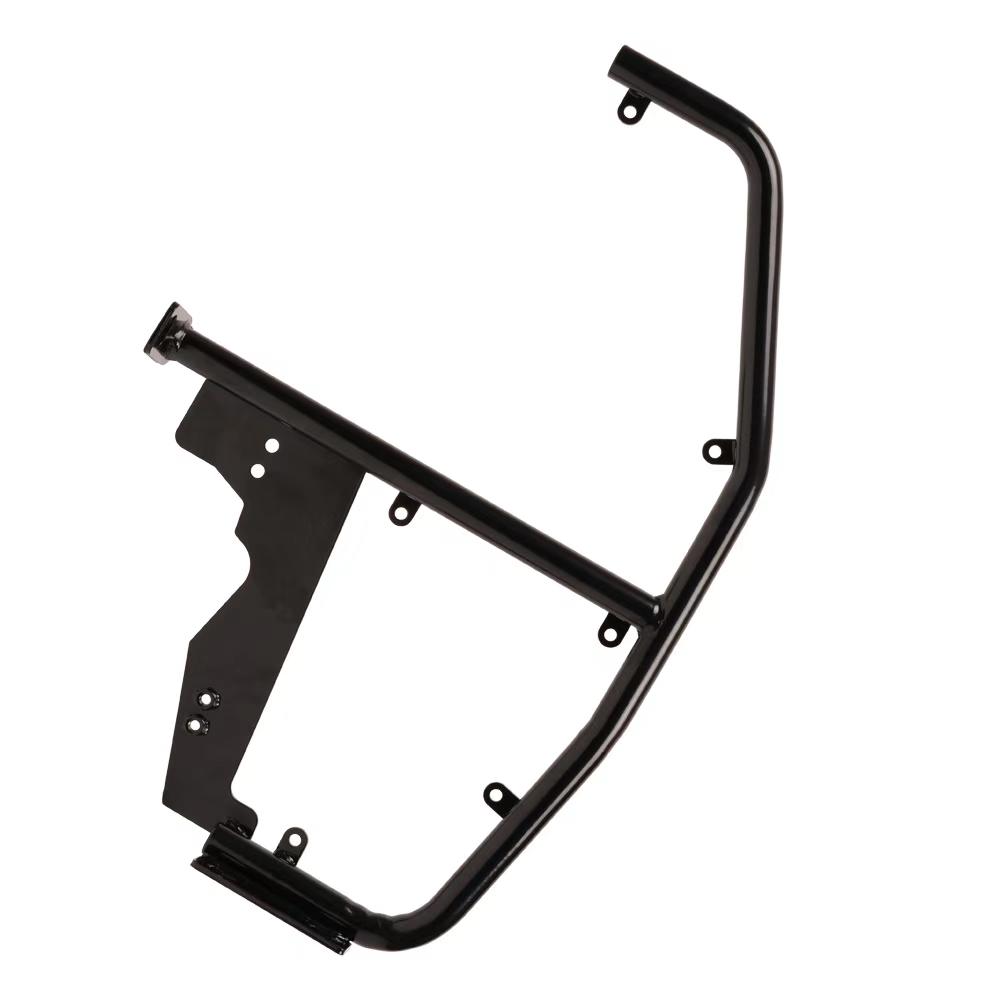

The support leg connector of this children’s safety seat are manufactured using a stamping and cutting process, which is more efficient and cost-effective compared to laser cutting. During the manufacturing process, stamping and cutting can process multiple pieces at once, resulting in higher production efficiency. Robot welding is used to avoid instability and quality issues caused by manual welding. The metal components are treated with black electrophoresis on the surface, which not only enhances the aesthetics but also improves corrosion resistance and ease of cleaning, making it more suitable for the requirements of a children’s safety seat.

For more Household hardware products that you like, please click on: Square tube welding fittings,support leg connector,Child safety seat hardware ,safety seat metal structural components, Yacht connection accessories, sim racing frame