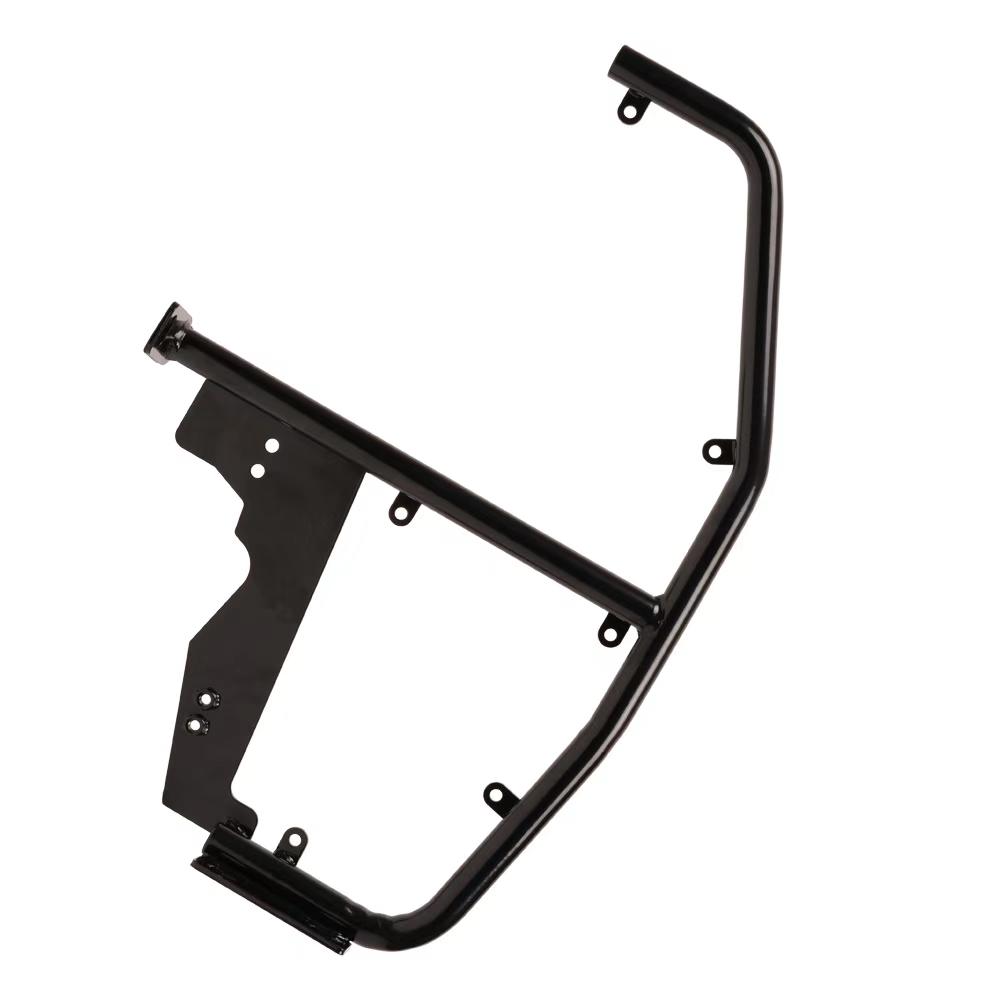

tractors gear lever assembly, which is a key system integrating multiple components and functions, mainly used to control the speed change and driving direction of the tractor.

What Is a Gear Shift?

This tractors gear lever assembly usually includes core components such as shift rod, shift mechanism, shift cable, etc., which work together to achieve the needs of the tractor in different working conditions.is aCustom assembly production.

The production of the stop rod is a rigorous and fine process, which covers a number of key processes, such as laser blanking, stamping, finishing, etc., to produce a finished product that meets the requirements of high standards. In this process, the raw materials used are equally diverse, including metal, plastic, rubber, etc., each material has its own unique processing characteristics and application scenarios.

During the laser blanking stage, the high-power laser beam is precisely controlled for efficient cutting of the raw material. For metal materials, laser cutting is able to quickly penetrate the material, forming smooth incisions, while reducing heat-affected areas and maintaining the mechanical properties of the material.

In the stamping stage, this process is crucial to shaping the shape of the stop rod. Under the strong pressure of the punching machine, the metal stop rod is shaped by the mold, and the desired shape and size can be obtained quickly and accurately. The plastic parts are injected into the mold by injection molding, and the mold is released after cooling and curing to obtain the finished product.

The finishing stage is a key link in the manufacturing process of the stop rod, which ensures that the dimensional accuracy, surface roughness and other related properties of the parts meet the design requirements through a series of precision processing methods and technologies, so as to ensure the smoothness of the parts in the assembly process and the smoothness of use.

Different surface treatment methods are used for different parts. Spraying and plating these treatments not only give the product a beautiful appearance, but also enhance its corrosion resistance, thereby improving the overall quality and durability of the product.

We are able to manufacture stop rod products that meet the needs of various application scenarios, providing reliable parts support for industries such as automotive and agricultural machinery.