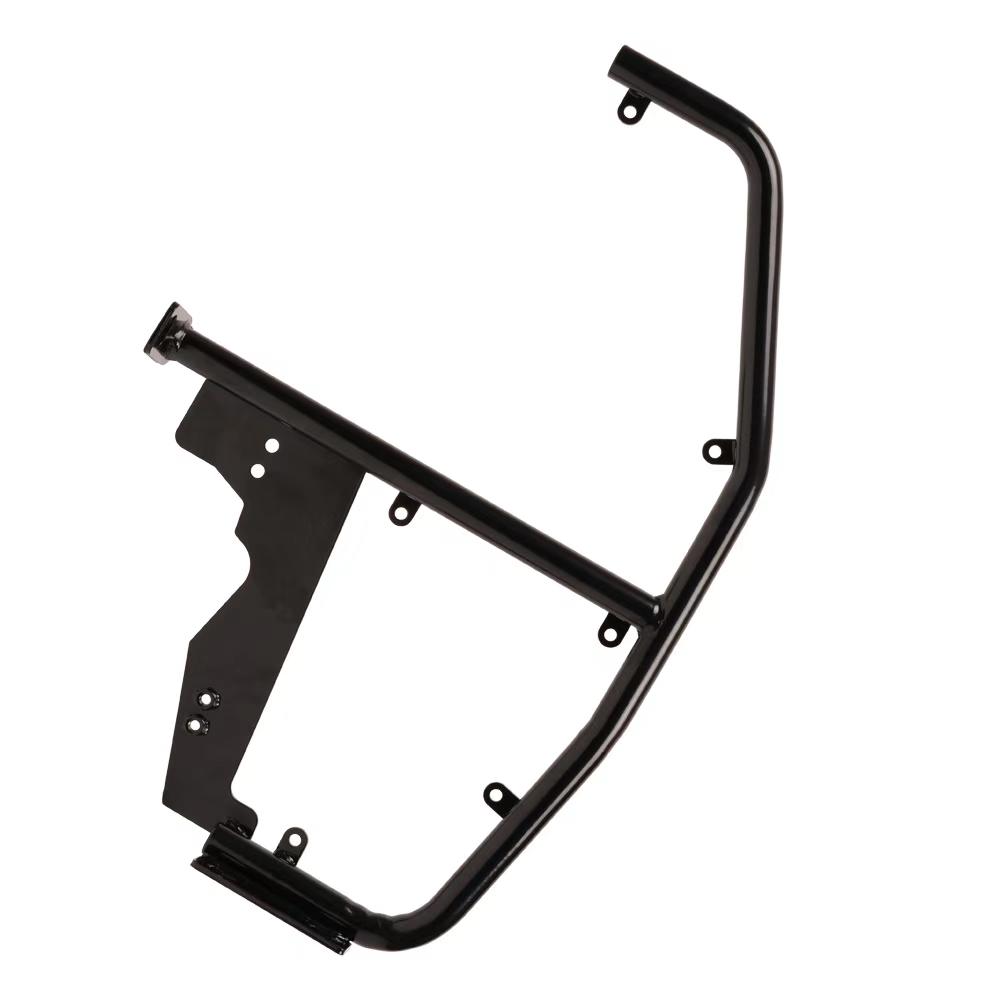

The sim racing frame is an all-in-one bracket that holds the steering wheel, pedals, gearshift and seat. This is a combination of square pipes, welded pipes, sheet metal and various hardware accessories. This article will explore the importance, knowledge and skills required, and production process of metal simulation racing frame manufacturing.

The production is completed through laser pipe cutting, CNC pipe bending, robot welding and other processes. . NBYOGO manufacturing requires extensive experience in metal processing and a deep understanding of racing performance requirements. In addition, our proficiency in CAD software and simulation software is also crucial for accurate design and simulation testing.

Production process

1, Design

The first step in manufacturing a metal simulated racing frame is design. Manufacturers need to design according to racing rules and performance requirements to ensure that the structure of the racing frame is reasonable, lightweight, and durable. At the same time, the design should consider the convenience of processing and assembly to reduce manufacturing costs and improve production efficiency.

2, Material selection

Material selection is an important step in the manufacturing of metal simulated racing frames. Considering the extreme environment and performance requirements of racing, high-strength steel, aluminum alloy, and other materials are usually selected. These materials have excellent strength, rigidity, and corrosion resistance, which can meet the stress requirements and long-term use of racing frames.

3, machining

Processing is a key step in achieving the design intent of a racing frame. Manufacturers need to use advanced CNC machine tools and mechanical processing technology to accurately process selected materials. Strict control of tolerances and surface roughness is required during the machining process to ensure the accuracy and stability of the sim racing frame.

4,assemble

Assembly is the process of integrating processed components. Assemblies have higher requirements for product production, and cumulative errors may cause assembly problems, which requires us to be more precise in the production of each component. The surface treatment of the overall electrophoresis makes the product exquisite and beautiful.

.